Endurance E-3120 Hub Replacement

Before 2023, the only option for a new hub was from the old Endurance supply chain. The original design is subject to poor longevity due to pin to hub wear, and questionable dimensional accuracy.

Unfortunately, experience shows that original Endurance hubs are heavily fatigued items with a limited life.

There have been numerous issues with cracking at the welds and porosity leading to hub arm failure.

This is why we previously offered our hub refurbishment service which has now been superceded by our new hub replacement service.

DC21 can now replace old and fatigued Endurance hubs with a new, stronger and more reliable model.

Replacing Faulty Endurance E-3120 Wind Turbine Hubs

Now, DC21 have collaborated with Serenity Wind to develop a new and exclusive E-3120 rotor hub, manufactured in the UK, featuring added design enhancements for improved performance, durability, and serviceability.

We initially trialled it on one of DC21’s own Endurance E-3120 wind turbines with exceptional results and have now installed over 40 new hubs across our own and customers turbines.

This means that we are now in the exciting position to be able to provide a new, British-made, field-proven hub for the E-3120.

Why Choose a New DC21 Rotor Hub for Your Endurance Turbine?

Here’s what sets our hubs apart from the original Endurance design and other alternatives on the market:

- Creating a stronger and more reliable connection: Key improvements encompass the selection of optimal alloy steel grades for the hub cores and hub arms. Serenity Wind evaluated several grades of welding wire to ensure an ideal welded joint. Once the weld was designed, it underwent rigorous testing by a UKAS-accredited metallurgical test laboratory to ISO 17025. The tests encompass mechanical, chemical, and microscopic examinations of the weld’s crystalline structure.

- Ensuring better quality and sustainability: The attachment has been significantly improved compared to the single “robotic” weld that we believe is used on the Endurance-style hubs. Although multiple-pass manual welding may take longer, it ensures that minimal thermal stress is locked into the finished part. It also allows skilled welders the chance to inspect each layer of weld applied and to grind out any observed imperfections during the weld process.

- Securing a seamless integration: As the welding process distorts the circularity of the bore, the hub core is only machined after welding has been completed. This ensures that the hub core has the correct geometry and a perfect fit on the shaft taper, minimising the stresses on the hub when tightening the tapers.

- Eliminating Vulnerabilities: After each weld is completed, it is machined back to profile and hand-polished to reveal any surface defects. This completely eliminates the risk of surface weld defects and significantly reduces the possibility of crack propagation from a small inclusion.

- Correcting Pin Hole Problems: The vast majority of Endurance Wind Power (EWP) hub failures previously occurred in the welded joint and the arm material in the vicinity of the blade pin hole. This new hub has a threaded blade pin with an M50 thread, which are fitted with an easily replaceable bronze brush. We have been using this bronze bush system since 2019 on original hubs, and the wear rate is favourable, with an expected service life of over 5 years on hub bushes. The hub bushes can also be swapped up tower without removing the blades.

- Reducing the threat of metal failure: This bush design not only provides a rapid and cost-effective repair route for the wear part, but it also does not impart any expansion force on the side of the blade pin hole. Expander pins work by expanding against the walls of the blade pin hole with a huge force, significantly increasing the risk of metal failure between the blade pin holes.

- Superior corrosion protection: Finally, the hub is thermally metal sprayed with zinc to give corrosion protection with a wax coating on the inside of the tube where the zinc does not reach.

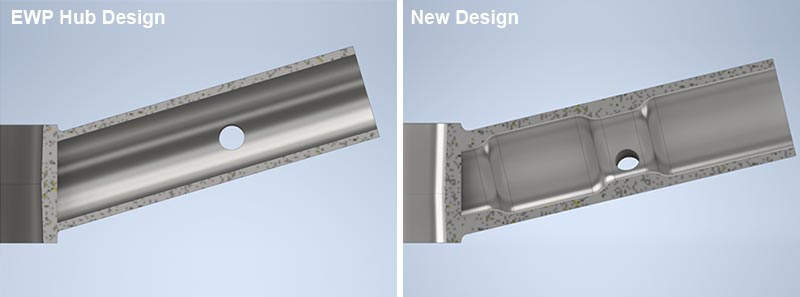

By comparing these 2 sections, the reinforcement of high-stress areas is apparent.

Is it Time to Replace Your Endurance E-3120 Rotor Hub?

DC21’s new UK-engineered rotor hub, designed and manufactured in the UK by Serenity Wind, will enhance your turbine’s reliability, performance, and service life.

Exclusively available for installation on your E-3120 by DC21 Operations Ltd. Contact us today to learn more or schedule an installation.

E-3120 Products, Upgrades & Repairs

E-3120 Low speed shaft (LSS)

DC21 can offer a new LSS that has been designed and manufactured in the UK. The design has several key features.

E-3120 Bedplate

DC21 can provide an alternative to replacing the bedplate by delivering a reinforced bedplate at a fraction of the cost of a new bedplate.

![]()

E-3120 Hub replacement

DC21 can provide complete refurbishment of the E-3120 hub, our hub removal tooling means there is very little risk of having to purchase a new hub.

Spring tubes

DC21 are pleased to offer the Serenity Wind spring tube upgrade with all E-3120 and E-4660 models. These spring tubes come with a 5 year insurance backed limited warranty.

E-3120 oil filtration

DC21 can offer a complete oil filtration retrofit for those E-3120s that did not benefit from oil filtration from new. Our kits come with the all important oil level switch system to protect the gearbox in the event of loss of oil.

E-3120 Reaction Arm

DC21 have worked with Nordlock to develop the Reaction Arm Expander pin for the E-3120.

E-3120 Gearbox Replacement & Repair

Fast, efficient and cost effective E-3120 gearbox replacement, overhaul and repair from DC21. We hold complete gearboxes & gear sets in stock to enable a rapid repair

E-3120 Brake Upgrade

New wind turbine braking system for the Endurance E-series that will reduce the strains placed on the turbine compared to the original braking system.

E-3120 Blade Holder Upgrade

New and improved flat root blade holder upgrade for E-3120, designed for superior performance, stability, and durability.