Wind Turbine Monitoring

Monitoring your Endurance wind turbine to ensure correct operation is achieved using Windsync for Endurance (WiSE). This system provides a broad overview of turbine performance and helps identify any anomalies for remote troubleshooting.

Condition monitoring, however, delivers insights into the health of specific and critical Endurance turbine components like bearings, gearboxes, low speed shafts, and generators, helping to predict maintenance requirements, before they become costly to repair or replace.

Condition Monitoring for Endurance Wind Turbines

What is Condition Monitoring?

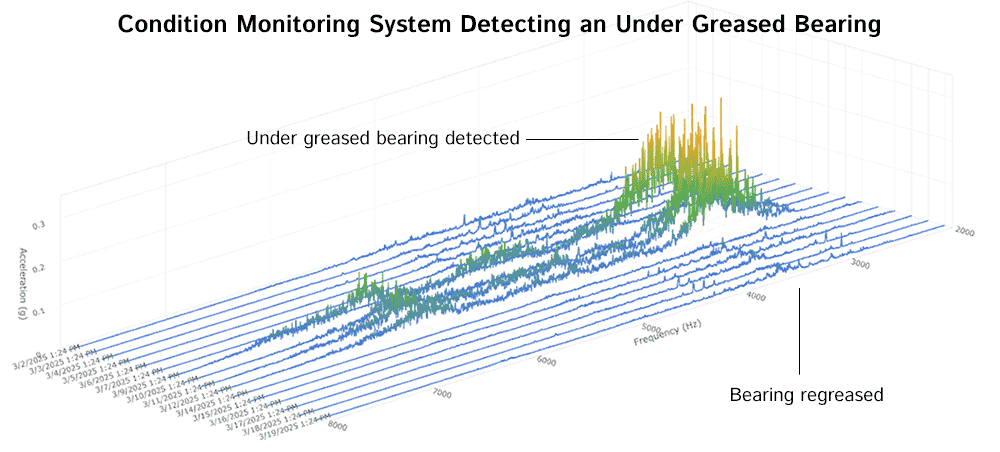

Condition monitoring is a useful system that provides in-depth details about a turbine’s condition, beyond the information remote monitoring systems yield. Whilst remote monitoring is very good at telling us when a turbine has developed a significant issue or shut down, our Condition Monitoring System (CMS) allows us to identify issues before they develop into a shut down, or lead to consequential damage. This enables preventative measures to be put in place, reducing downtime, and minimising repair costs, sometimes by many thousands of pounds.

For example, discovering an under greased bearing could prevent a worst-case scenario costing over £20,000 if a nacelle needed removing for bearing replacement.

New Dynamox CMS for Superior Turbine Performance

After reviewing the technologies available in the market place, DC21 chose Dynamox CMS for our own fleet of wind turbines. It uses wireless triaxial sensors with a 5-year battery life to provide early warning of mechanical deterioration. Most of the sensors are mounted magnetically, enabling them to be easily placed on different parts of the turbine.

This includes, for the first time, mounting a sensor directly on the low speed shaft (LSS), which should improve detection of any LSS issues. The CMS systems will also allow detection of issues that can affect turbine production, such as:

- Early detection of bearing fatigue, misalignment, or lubrication issues

- Early detection of vibrations or irregular loading patterns

- Detection of gearbox and main bearing issues

- Allowing for preventative maintenance, so parts can be replaced before they fail. This extends turbine life and reduces downtime

- Reduction or elimination of emergency repairs, often requiring cranes and extended downtime

DC21 is now excited to be able to offer this new condition monitoring system to all our customers.

How Our new Condition Monitoring System Works

When the new Condition Monitoring System is first installed, it transmits data from the sensors to Dynamox servers. Over the first 4-6 weeks data is gathered and analysed to develop a baseline. After this, the system will automatically alert DC21 if any abnormal conditions are detected.

We then remotely investigate the turbine using the Windsync and Dynamox platforms to determine next steps, such as:

- No action, continue to monitor

- Site visit to investigate (standard O&M fees apply)

- Dynamox “deep dive analysis” to investigate the cause of the alert

If you would like to find out more about the new Dynamox condition monitoring system, designed to enhance your Endurance Wind Turbine Performance and cost-efficiency, contact DC21 today.

Our team of trained and experienced Endurance specialists will provide you with all the information you need to make the best decision for you and your turbine.

What is Remote Turbine Monitoring?

Remote Monitoring is a platform which connects to the control system within wind turbines.

The control system is a programmable logic controller (PLC) at the base of the turbine. The platform connects via a virtual private network (VPN) tunnel using a small piece of hardware, allowing turbine owners to monitor the health and performance of their wind turbine from anywhere in the world, requiring just an internet connection and login.

Data is accessed from a secure application, downloadable on a mobile, tablet device, or web browser.

WindSync for Endurance (WiSE) – Remote Monitoring System

DC21 has been operating and managing Endurance wind turbines for over 13 years. Before Endurance ceased trading, DC21 had already begun working with VisualWind, an organisation developing software for the renewables energy industry through digital innovation.

With Endurance’s demise came great uncertainty over the future of the Endurance platform, the ability to control the turbines, limited insurance availability, and the security of who may have access to the data from these turbines. DC21 and VisualWind, a renewable energy software company, combined their collective skills and experience to develop WindSync for Endurance (WiSE).

WiSE is a supervisory control and data acquisition (SCADA) software solution, used by DC21 as an alternative to the unreliable remote monitoring system offered by Endurance.

DC21 migrated its entire fleet of Endurance turbines to WiSE within six weeks of Endurance going bankrupt.

WiSE Remote Monitoring and Control

WiSE provides a fully independent remote monitoring and control system for Endurance turbines. The software offers all Endurance E Series wind turbine owners a robust and fully featured alternative to the software previously operated by Endurance Windpower, known as ERIC. WiSE is used on both Endurance E and X Series and other branded turbines. Whilst the monitoring functionality is limited on the X Series, it does allow you to create VPN access for Mita-Teknik control software.

100% Control of Endurance Turbine Features

WiSE was developed to allow turbines to be monitored, controlled, and operated, completely independently of any third parties. Condition monitoring systems, like Dynamox, transmit data from sensors placed on the turbine to WiSE for trend analysis and identifying potential threats before they happen.

WiSE works hand in hand with Dynamox to provide the best protection for your wind turbine

WiSE allows the user to have 100% of the control features of their Endurance turbine, including manual mode, smart idle, and locking.

Key benefits and advantages of WiSE:

- Puts complete control in the hands of the turbine owner

- Live data direct from turbine(s)

- Compatible with desktop, tablet and mobile devices

- Enhanced data analysis provides a visual power curve

- Other features such as downtime analysis

- Brings big wind analytics to the small wind market

- Transparency of turbine performance and reliability

Speak to our team of specialists to discuss how WiSE could benefit your Endurance wind turbine.

Out of Hours Monitoring / Technical Support

DC21 constantly monitor the fleet of Endurance turbines within the normal office working hours of 8.30 am-5 pm; any issues that may occur within this timeframe are investigated and reacted to within 30 minutes of the Remote Monitoring System alarm being triggered.

Where a problem can be fixed remotely our technicians will often have your turbine back in service before you even notice it has shut down.

Our technicians also closely monitor the fleet out of office hours. In the event of a shutdown or technical issue, our technicians will rectify this remotely. If a site needs to be attended, we will contact you to provide the options available to get the turbine back into service.

Our service also includes regular checks on critical systems such as the turbine brakes. It is crucial to ensure your brakes are in a suitable condition to apply the correct torque whenever a brake event occurs.

Contact DC21 for Further Information on WiSE and Dynamox CMS Today.

Please see the other services we have available below:

Our Turbine Services

Turbine Maintenance

DC21 offer both scheduled (typically every 5,000 rotational hours) and unscheduled (an activated alarm or condition that is developing) maintenance packages for your turbine.

Turbine Breakdown

In the event of a turbine shutdown, DC21 will inform the customer of the occurrence and provide the options available to get the turbine back into service quickly.

Turbine Overhaul

DC21 can overhaul your turbine with the minimum of fuss and disruption using our tried and tested methods.

![]()

Turbine Monitoring

DC21 can offer both condition monitoring and remote monitoring & control systems for Endurance turbines.